No products in the cart.

What is the Conveyor Belt Cleaning System?

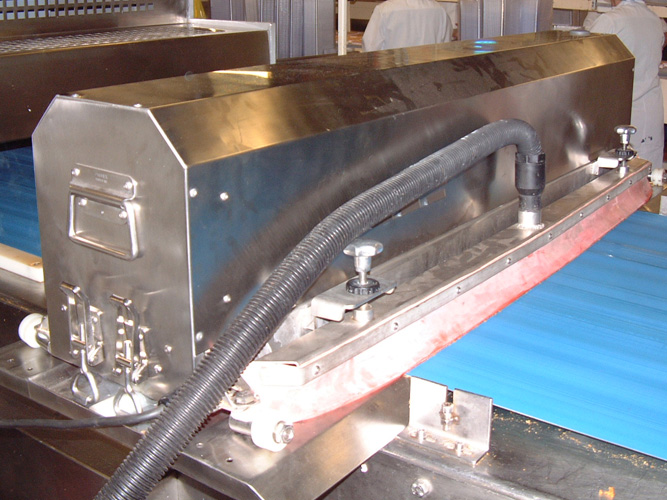

The Conveyor Belt Cleaning System is a steam cleaning device that has been developed to improve various standards associated with traditional conveyor belt cleaning methods. Attaching to a range of Tecnovap steam vacuum machines the Conveyor Belt Cleaner uses the power of continuous superheated dry steam and vacuum to hygienically clean and dry conveyor belt systems.

The Conveyor Belt Cleaning System can be used as either a permanently fixed intergrated unit or a portable mobile unit. This setup usually depends on whether there is a single conveyor belt or multiple conveyor belts that require cleaning. Most commonly portable units are required as many single conveyor belts do not have space for a permanently fixed unit and larger conveyors often have multiple change over points.

Technology Parts of Conveyor Belt Cleaning

The Conveyor Head

The System combines brush agitation whilst at the same time introducing the cleaning agent through the core of the brush.

The conveyor belt travels over an underbelt tray to ensure that the belt is presented parallel to the cleaning head. In some applications where more moisture is required for the cleaning process, the unit can be used with hot water washing systems.

In the majority of cases steam and agitation is quite sufficient but if required chemical dosing or an after-clean sanitiser can be introduced. Units are built in widths, starting from 300mm and increasing in 100mm increments to 2 metres.

The Control Panel

To extract moisture while cleaning to help eliminate the need for towels required by conventional steam cleaners that include no extraction capability.

Belt Types

The Conveyor Cleaning system can be used to clean Smooth (PV or metal band) belts or modular belting.

Belts with small flights can also be cleaned but in these cases drying is not guaranteed.

Where a modular belt is required to be cleaned a food grade fusion bonding is applied to the tray to avoid the chemical reaction often found between stainless steel and modular belt material.

The Conveyor Cleaning System can also clean the following different types of belts:

Smooth White Conveyor Belts

Food Conveyor Belts

Interlock Conveyor Belts

Metal/Wire Conveyor Belts

Mesh Conveyor Belts

Brush Core

A range of brush cores are available, ranging from soft bristle for modular belting through increasing stiffness grades and culminating in stainless bristles for wire mesh belting.

How to Clean Conveyor Belts

Cleaning of conveyor belts has tradionally been a difficult time consuming task that had been done by hand and required shutting down the conveyor system. Thankfully Tecnovap have now developed a far better, more efficient and easier method to hygienically clean conveyors; all without chemicals.

The Conveyor Cleaner by Tecnovap uses a combination of superheated 94% dry steam vapour, a motorised scrubbing brush, water/detergent injection, and a wet vacuum to treat conveyor belt systems as they run.

To clean simply:

- (if portable system) Attach the Conveyor Cleaner to the appropriate position on the conveyor system;

- Connect the steam generator and vacuum system of the JetVac or SteamBox;

- When steam is ready adjust the Conveyor Cleaner squeegee and brush onto the belt so there is contact;

- Run the conveyor and turn on the steam and vacuum to start cleaning. The steam will emulsify soiling, the brush will break down and the vacuum will remove simultaneously;

- Once the belt is clean (usually a few cycles) simply raise and turn off the Conveyor Cleaner system.

The conveyor system is now clean and sanitised. All with minimal physical effort, very little water, no chemicals, and no mess.

The Conveyor Cleaner can also be permanently fixed to the conveyor belt system.

Advantages and Benefits of Using Conveyor Belt Cleaner

Benefits:

Traditionally cleaning of conveyor belts has been regarded as an very laborious task that requires lots of time and physical effort; especially in extreme cases where conveyor need to be dismantled to clean. The Conveyor Belt Cleaning System on the other hand actually enables conveyor belts to be cleaned to a higher and more consistent standard whilst in place and operating; therefore saving hours/days of manual labour time.

In addition to time saving the Conveyor Belt Cleaner also reduces both water and chemical usage. This is possible through the use of continuous 94% superheated dry steam that requires less than 15lt of water per hour. Extra high +180°C steam temperatures produced by Tecnovap steamers also sanitise most surfaces on contact eliminating the need for most chemical disinfectants.

The added benefit of vacuum extraction leaves flat conveyors in a mostly dry state and immediately ready for use. This vacuum extraction combined with low water usage also makes the CCSS ideal for use on conveyor belts in areas without built in drainage.

Advantages:

- • The belt is cleaned much more quickly and consistently, releasing it back to production with the minimum of delay.

- • Low water usage, typically less than 20 litres / hour, saves on both water costs and effluent disposal.

- • Vacuum extraction leaves the belt in a dry state. On a smooth belt, for example the belt is dry and ready for use immediately.

- • The combination of low water requirement and vacuum extraction makes the unit suitable for production facilities without built in drainage.

- • Use of the unit allows benefits to be made by improved labour utilisation, as well as the advantage of mechanical action giving a consistent and uniform cleaning regime.

Ideal Industries for Conveyor Belt Cleaner

Food Processing Plants

- • Sanitise Conveyor

- • Remove food build up

- • Speed clean and sanitise other food processing equipment like benches, machinery and ovens.

Pharmaceutical

- • Sanitise Conveyor

- • Vacuum and remove dust

- • Deep clean hard to reach areas and other equipment

Industrial

- • Sanitise and disinfect engineering systems

- • Deep cleaning winery conveyor belts

- • Cleaning warehouse and logistics conveyor belts

Unique Features

Conveyor Belt Cleaner

165-180°C Dry Steam

165-180°C superheated dry steam is great for sanitising the conveyor belt surface and cutting through hard to clean soiling like oils and fats.

Portable or Integrated

The Conveyor Belt Cleaning System can be used as a fixed system for cleaning a single conveyor or as a portable system for cleaning multiple conveyors.

Continuous Steam

The steam generators that power the Conveyor Belt Cleaning System all feature continuous steam production and have large water capacities.

Control Box

The electronic Control Box is used to regulate the amount of steam released onto the conveyor belt. The unit can be mounted on the conveyor or on the steam generator.

Superheated 94% Dry Steam

The JetVac / Steam Box steam generators largely reduce water use by producing 94% dry steam that requires only about 15Lt of water per hour.

Conveyor System

The Conveyor Belt Cleaning System can be used to effectively and efficiently clean a variety of different style and different sized conveyor belts.

Accessories for Conveyor Belt Cleaning System

The Conveyor Belt Cleaning System comprises of four main components:

- •Standard 600mm Mountable Squeegee

- •Electronic Control Box

- •2.5m Vacuum Hose

- •Steam Bacchus Hose 12P

* Suitable Tecnovap steam vacuum system is not included and must be purchased separately.